APARN2023 Asia-Pasific Artistic Research Network 2023 | by Dyah Retno Fitriani, (orcid link)

Abstract

Each factory must have its own waste, as well as a ceramic factory. Dewata company located in Kasongan, Yogyakarta, has been using Sukabumi clay and producing waste around 40 Kg/Day. These waste clays are not being reprocessed again, but they are being sold at a very cheap price. The writer divided the waste clay into three samples which will be tested into several different techniques. After the waste turned into formations, they are being burned with a temperature of 750 o, 1060 o, and 1200 o C. After that, these tests will be made into artworks with an object called 'Radiolaria'. Radiolaria is a plankton that has morphological parts such as chest, abdomen, anus, thorns and pores on its body. When radiolaria feels threatened at night, it will issue a ray which is a result of enzymes friction on its body. The benefits of radiolaria, other than as a scrubber, is to measure the age of the earth, maintain the balance of temperature, and be an indicator of petroleum. In these artworks, the writer also conducted laboratory tests with ICP method to determine whether the waste clays are dangerous. Tests with Pb indicator as one of the heavy metals resulted in clays containing Pb waste 365.10 mg/kg. According to DIY regulation on quality standard of ceramic's company, liquid waste in ceramic should be equal to 1000 Mg/Kg. The writer proved that these waste clays are safe.

The writer's artworks, which utilized the waste clays with radiolaria objects, achieved the most artistic results with sample I clay. In the making of radiolaria ceramics, the printing technique is the most suitable technique. Radiolaria has a symmetrical shape and printing technique that can give perfect global repetitions. Meanwhile, sample II and III clays can be used as additional decorations such as thorns, bulges, or others. The ceramic combustion process can cause unexpected artistic effects, for example like reduction at the beginning or at the end of combustion with 30 minutes of detention can result in a separate cracked glaze artistic effect.

Keywords: Waste clay, Radiolaria, Ceramic.

Introduction

1. Creation Background

So far, the use of clay is processed from raw materials in the form of good stone clay from Sukabumi, Pacitan and several other areas with mineral content in the clay that is still intact. Pure clays have the chemical formula Al 2 O 3 + 2SiO 2 + 2H 2 O, which are easier to handle and form and their content has been extensively studied. This convenience is obtained because pure clay still has complex plasticity and porosity properties. While the waste clay has been heavily contaminated and a lot of minerals have been absorbed from previous use. So that the plasticity is reduced, it usually contains a lot of sand and water glass. This shortage causes waste clay to be disposed of or sold cheaply.

Dewata Keramik Company is a ceramics factory in the Kasongan area of Yogyakarta, which produces functional craft items in the form of glasses, bowls, aromatherapy, and so on. Every ceramics factory will produce clay waste, so does the Dewata company. “ It is unavoidable that when making your pottery, you will create a certain amount of waste clay, whether this comes from slab offcuts or the inevitable mistakes ” (Mattison, 2001: 24).

The writer will express the experimental waste clay material from the Dewata company in the form of a radiolaria object to become a work of art. Radiolaria is one of the plankton that lives in the ocean. Plankton are tiny creatures, which can be animals or plants, that live in water.

The objects of waste clay and radiolaria are closely related to environmental issues. The remaining waste clay mixed with glaze waste, either intentionally or unintentionally, then disposed of carelessly and continuously will affect water quality, especially in a factory environment. Considering that the Dewata company uses low temperature glaze which contains a lot of heavy metals such as Pb (lead), besides that this factory is located in the middle of a village so in the long term it will be very worrying if this company is unable to process its own waste.

The creation of works that elevate waste clay to be expressed as radiolaria objects will begin by experimenting with waste clay formulas with a mixture of plastic materials such as kaolin, silica, ball clay and so on. Three clay formula will

Tried in various ceramic forming techniques such as casting, plate, Pinch, and Coil techniques, then glazing will be carried out to find a suitable glaze and temperature to be applied to the formula for each clay for the firing test.

2. Formulation and Purpose

There are various problems behind the creation of this work of art, so to limit it, two formulations of the problem are concluded, namely Why is waste clay attractive to be used as a material for expressive ceramic works? and how is the visualization of expressive ceramic works that can be realized with this material? The purpose of this creation is in addition to obtaining new knowledge from waste clay processing which is reviewed based on waste clay experiments on radiolaria objects as well as realizing or visualizing the author's expressions related to the use of materials and the application of techniques in treating waste clay with radiolaria objects.

3. Theory and Methods of Creation

Research-based practice is a way of doing or creating something that is based on things that must be researched and can be accounted for. The creation of this work began with collecting data in the form of interviews regarding waste clay at Dewata's company by employees who worked there. Then from the clay obtained, the author will conduct laboratory tests to find out what content is in the clay. The author will then process the waste clay into raw materials that are suitable for reuse in making ceramics. The processing was carried out by mixing, forming, glazing, and burning experiments. The experimental results can then become a prototype before being made into works. So that in this creation, not only works become superior products but also able to contribute knowledge that can be reviewed scientifically. In line with the thoughts of the authors, Smith and Dean (2009: 1) state that: Creative work within the university environment is now often referred to as practice-led research, practice-based research, creative research, or practice as research. The terminologies are a means to characterize the way in which practice can result in research insights, such as those that arise out of making a creative work and/or in the documentation and theorization of that work. Several of our authors suggest that practice-led research can develop unique processes for creative work and for research.

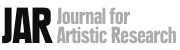

Waste clay obtained from the factory as described in the chart above, then processed again by the author. In the initial stage of processing, the clay is soaked in water and then stirred with a drill mixer to melt the lumps of clay. Then the clay that has been soaked is filtered using mess 80 to separate the clay from the garbage that is mixed in the soaking. Screening the three samples produced clay with the following criteria:

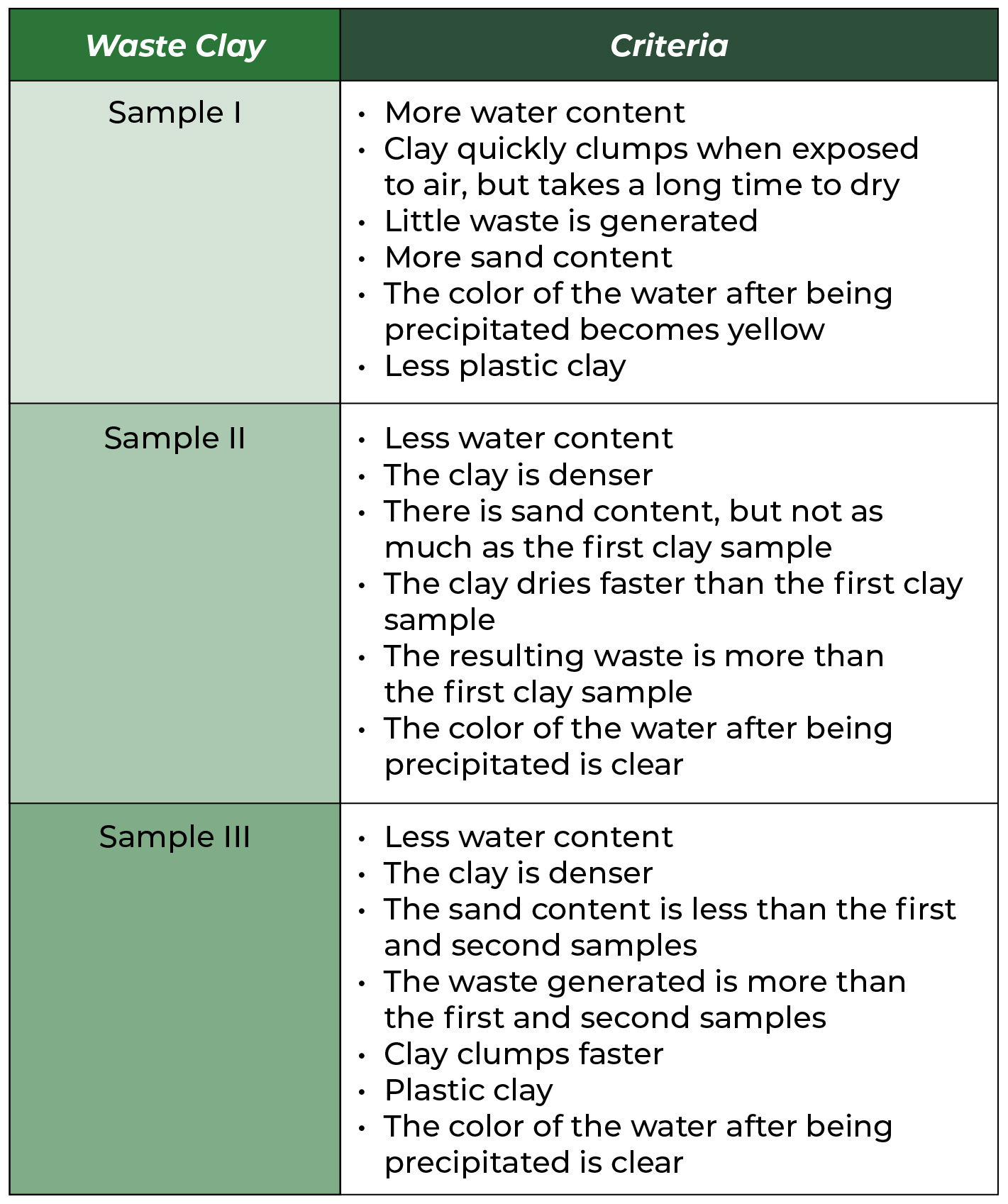

The results of the analysis are taken into consideration in making the formula, namely:

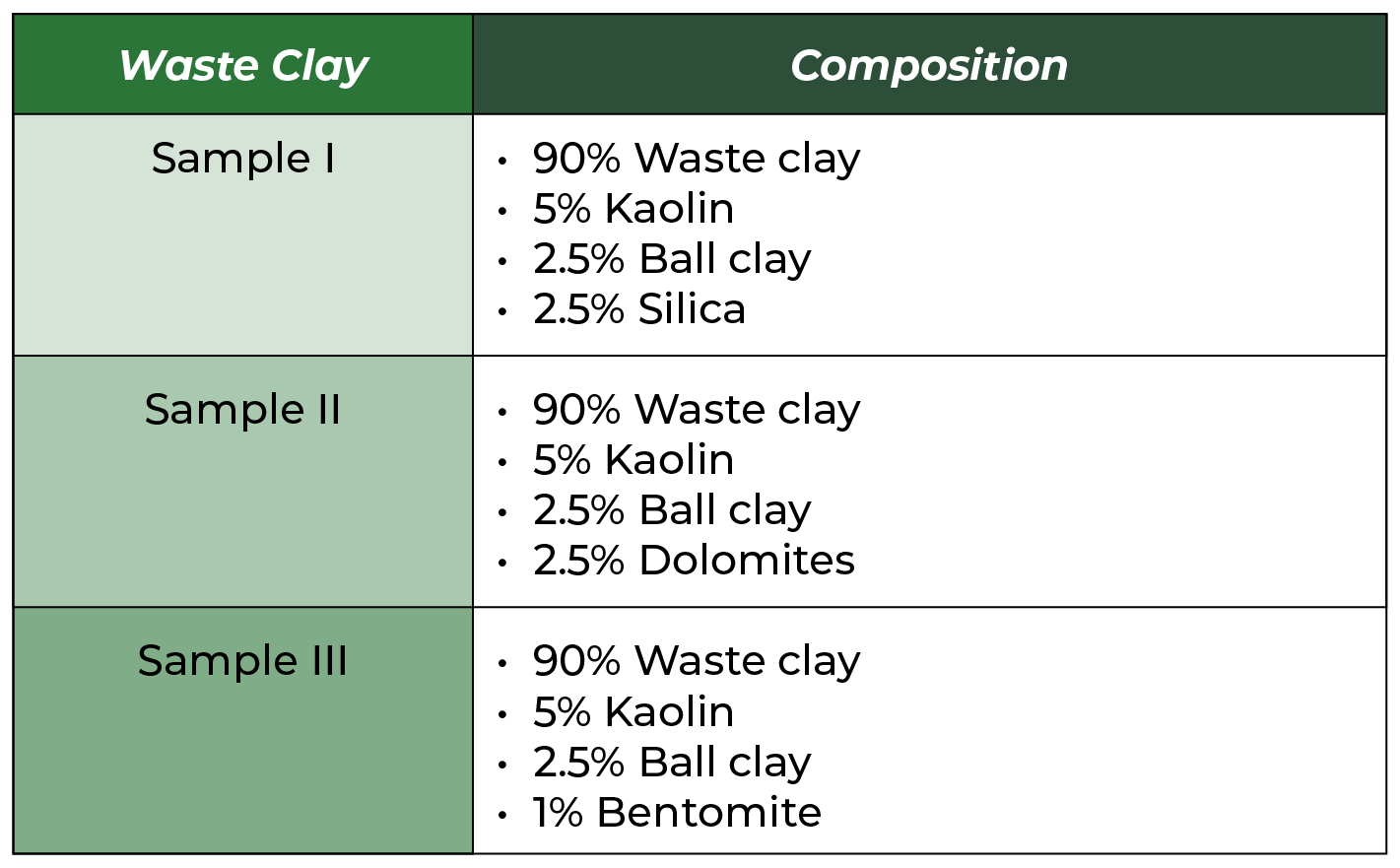

After the clay is mixed with the supporting material, for half an hour with a mixer the clay is mixed until blended. The results of the analysis after mixing with the above percentages are:

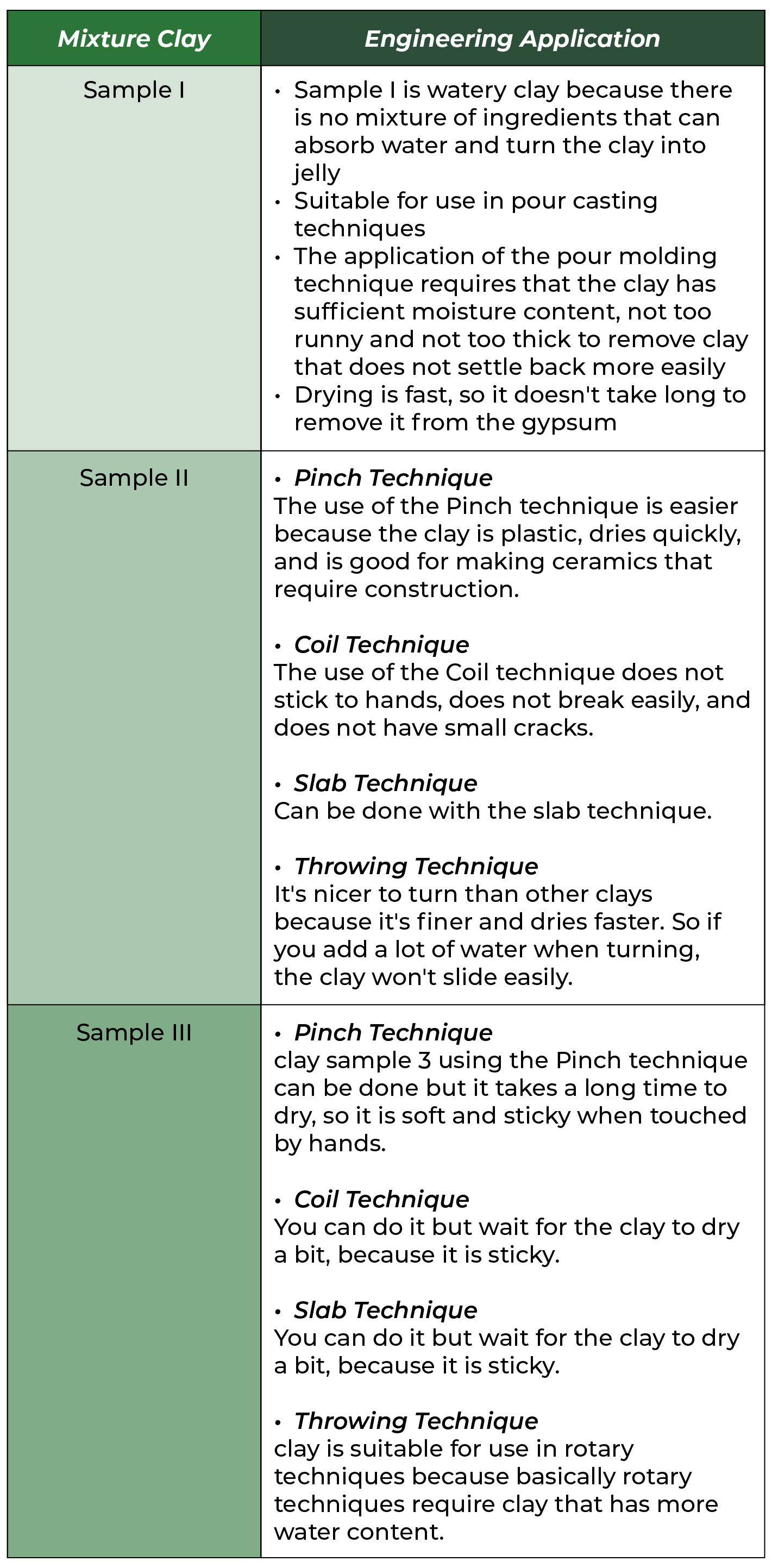

The results of the clay mixing above are then carried out using Pinch, molding, Coiling, rotating, and slab techniques. Sample I is only suitable for use with the pour molding technique because the material is very watery, while samples II and III are suitable for use with the hand-building technique, after the clay has been dried in gypsum. The results of the analysis for the application of each clay with ceramic techniques are as follows:

- Clay Sample I

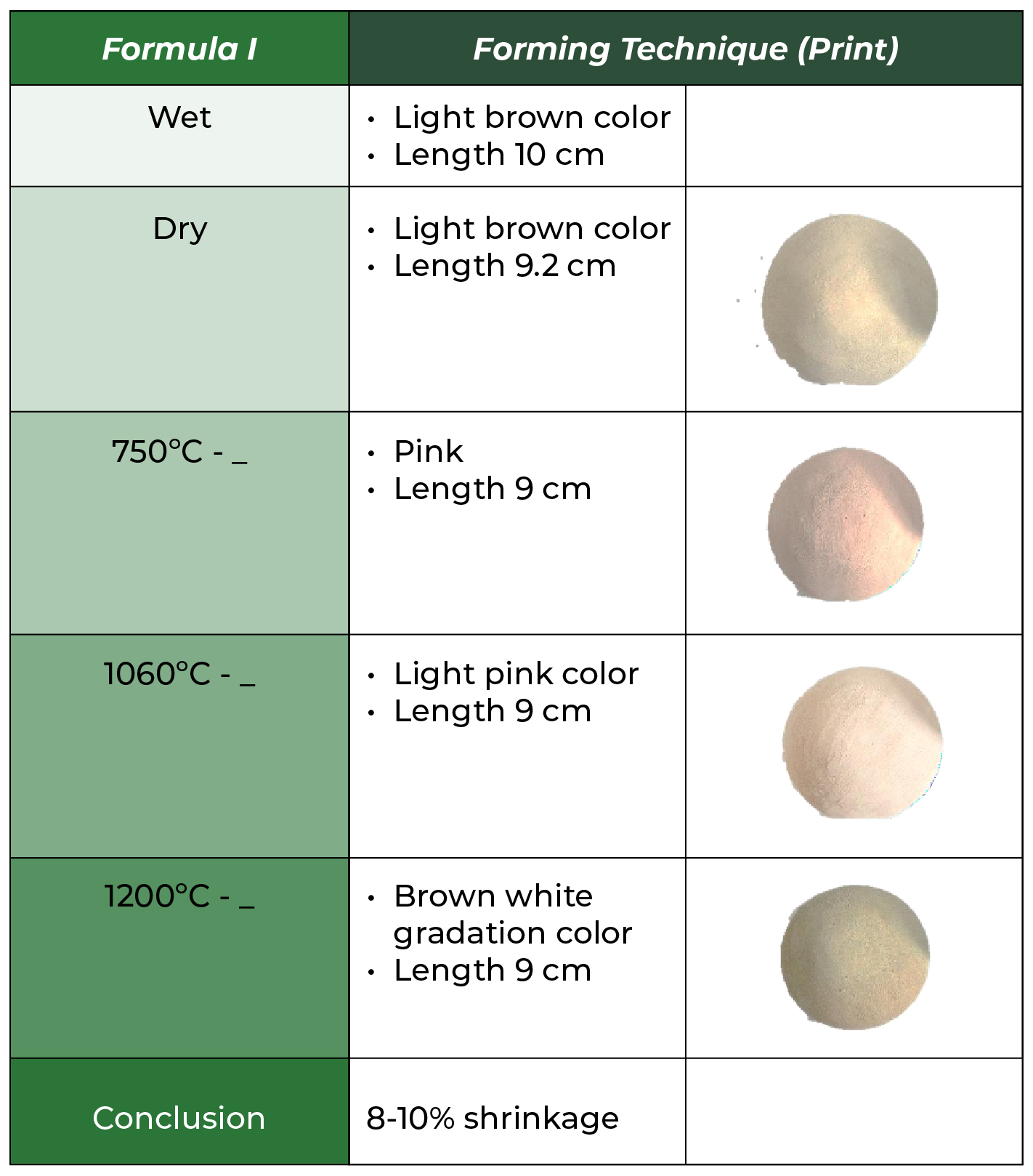

Clay sample I is treated waste clay with a composition of 90% waste clay, 5% kaolin, 2.5% ball clay, and 2.5% silica. The results obtained from this mixture have been tested and produce a type of clay that can only be treated with the pour molding technique. The results of the analysis are as follows:

- Clay Sample II

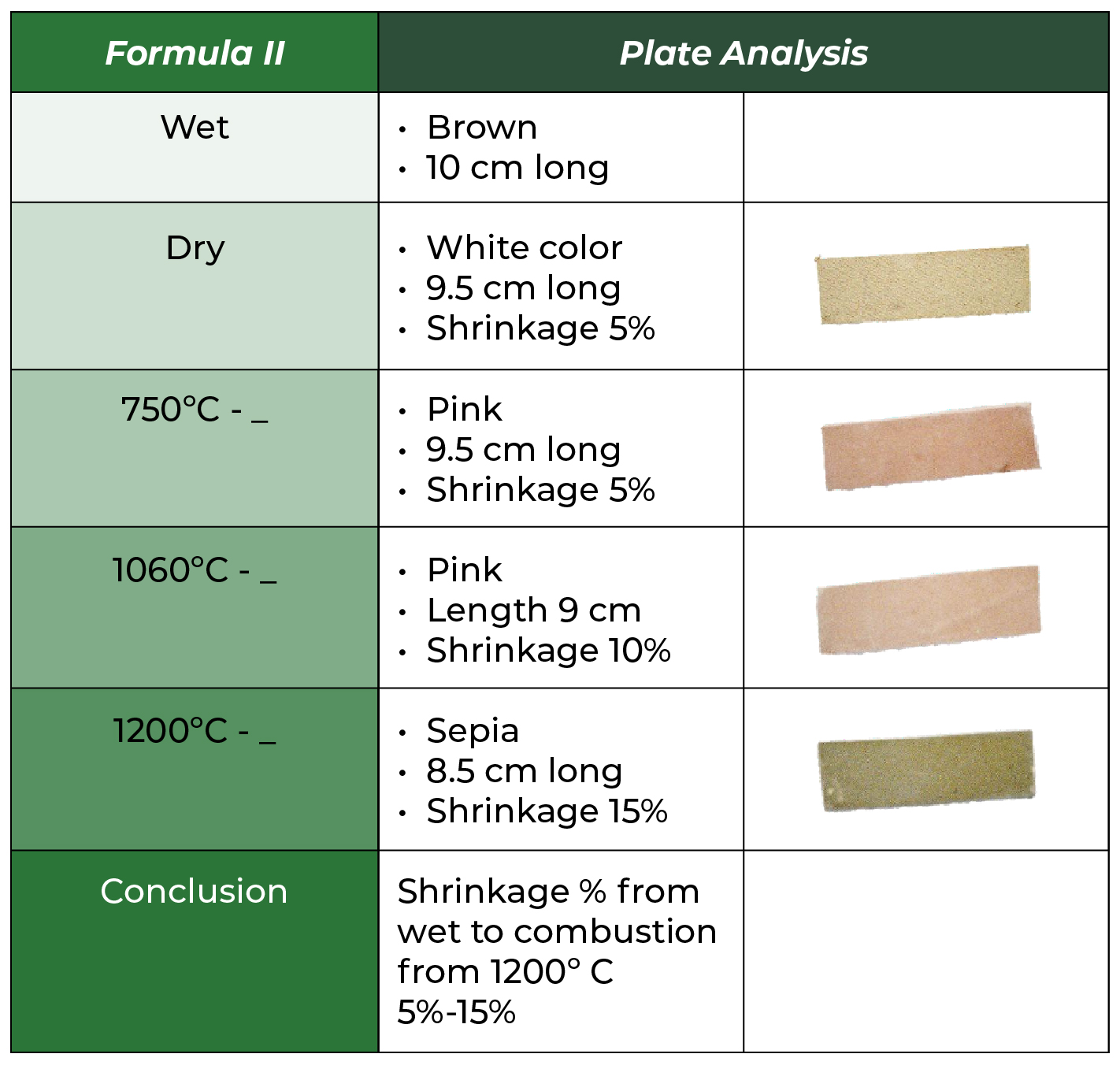

Clay sample II is treated waste clay with a composition of 90% waste clay, 5% kaolin, 2.5% Ball clay and 2.5% Dolomite. The results of sample II clay after being mixed made this clay very viscous because it used 2.5% dolomite whose function was to absorb water and thicken the clay. So this clay is suitable for making ceramics with dense techniques such as Pinch, Coil, plate and rotate. The clay that has been mixed and thickened is then poured into the gyp to dry. Drying is done by letting it dry and just letting it air out for further kneading. Then analyzed the plate to determine the color and shrinkage from wet to burnt from 750 o C to 1200 o C.

- Clay Sample III

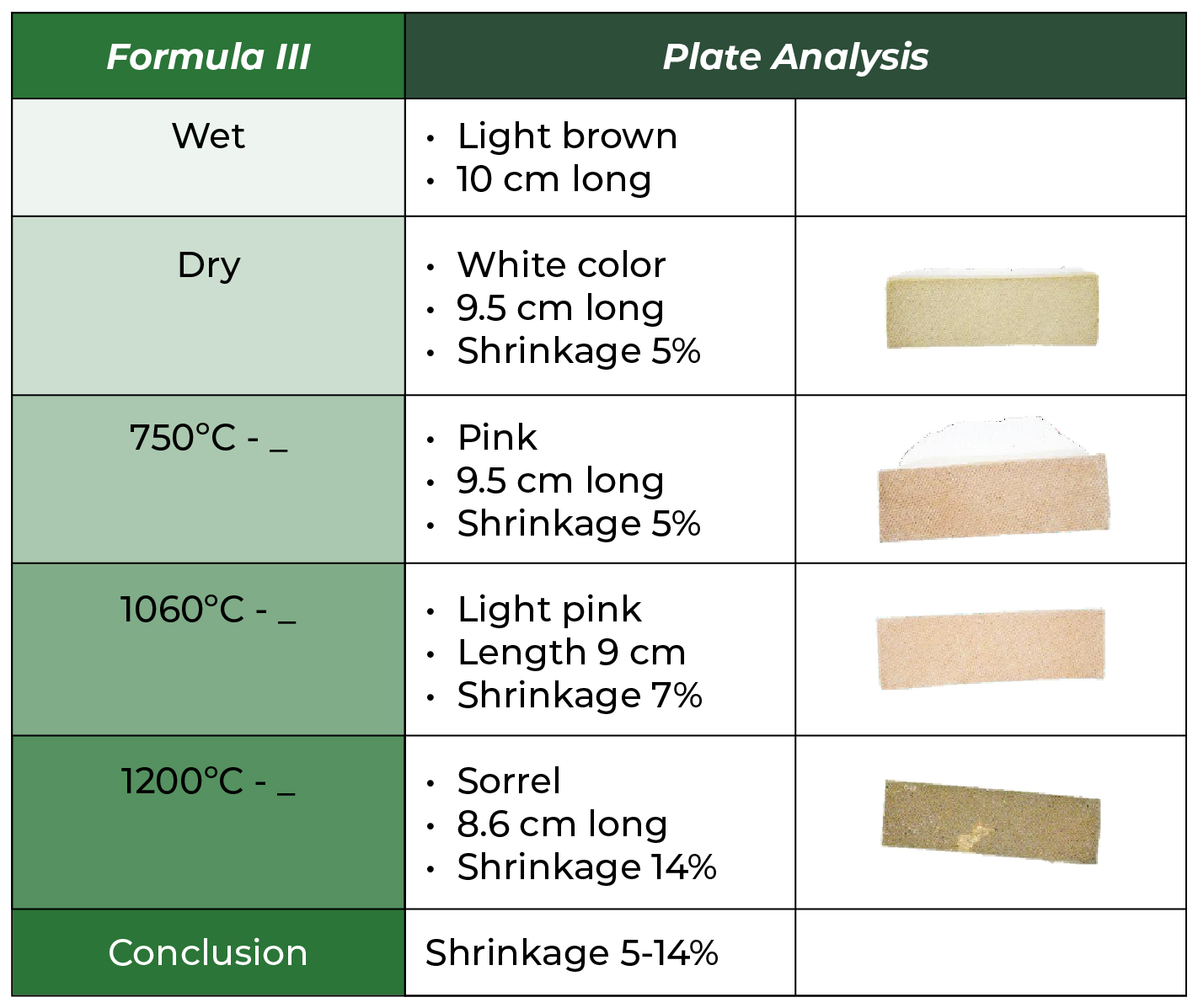

Clay sample III was processed from 90% waste clay, 5% kaolin, 2.5% ball clay and 1% bentomite. The results of processing sample III are also suitable for making solid clay using handbuilding techniques of Pinch, Coil, plate and turn. Sample III took longer to dry due to the use of only 1% bentomite, so it needed additional time to dry and it often got sticky in the hands or was plywood when Coiled.

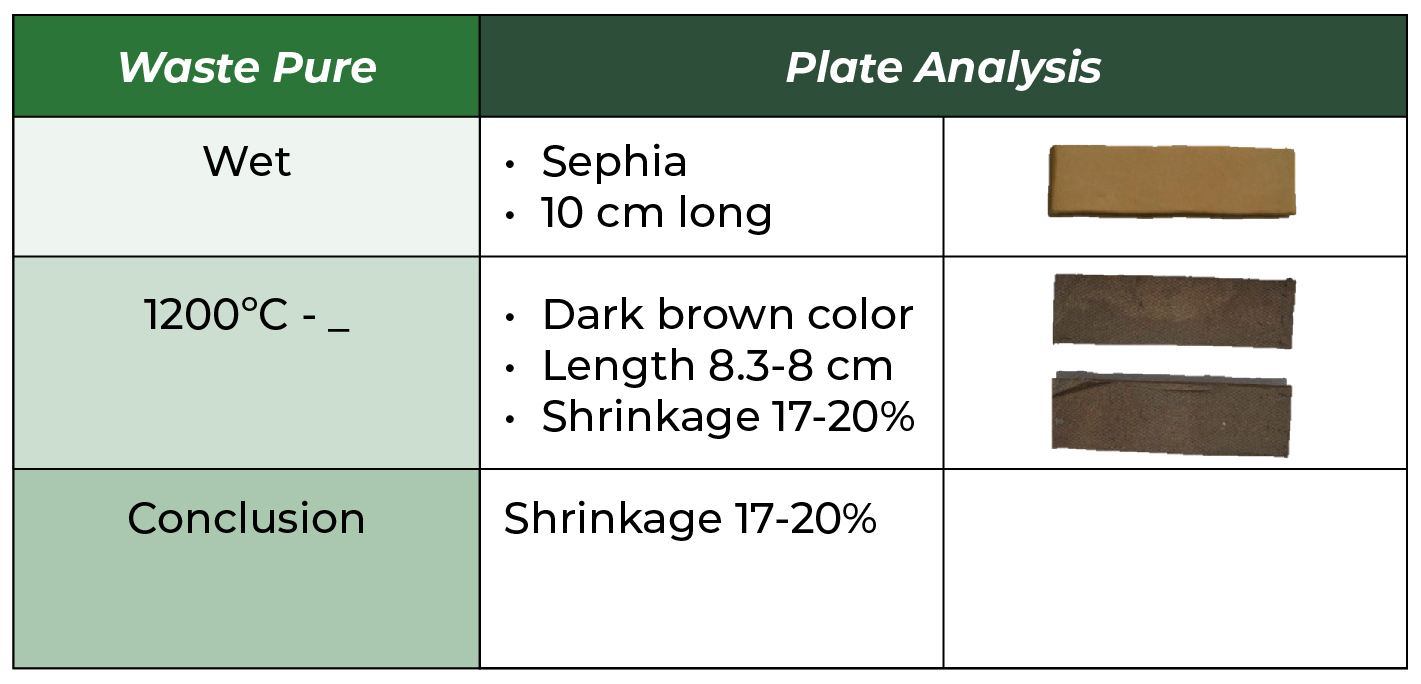

Comparison of pure waste with formulas I, II and III has quite a significant difference, especially in terms of shrinkage, color and treatment. In pure waste, clay yields are obtained which cannot withstand high temperature burning of up to 1200o so that the color is black and the clay shrinkage is the highest compared to the others, namely as much as 15%. While the clay that has the lowest shrinkage is in sample I as much as 8-10%, then sample II as much as 5-15% and sample III as much as 5-14%. Pure waste clay can only be used in two Coil and plate techniques, while clay samples II and III can be used for four techniques, namely Coil, Pinch, plate and turn, and sample I can only be used for the pour molding technique.

The above work is the result of a formation trial with waste clay in each sample which is burned at different temperatures. There are differences in color and size. Change of pure waste clay, as well as the resulting waste and clay mix results. The experimental results above prove that waste clay can still be reused as an alternative medium. In this creation process there are unexpected and unexpected things. Unexpected things that the author looks at in this creation process, starting from the waste clay which was experimented on in 3 samples. Where in each sample there is actually only one differential material, but it is beyond expectations that from one sample difference there is a big difference in the change. The first sample still contains a lot of water, so it is used for the casting technique. Meanwhile, the second and third samples could be very thick, which was never imagined by the previous authors. So from this experiment, the authors know how to differentiate in making clay for casting and handbuilding techniques .

The things that the writer can predict in this creation process are that clay can be used to apply the five ceramic techniques, because the composition of the clay that has been made starting from the dough looks plastic and can be shaped. However, the authors found from each analysis that each sample had its own advantages and disadvantages. For example, sample one is good for printing techniques, but not better than samples two and three for handbuilding techniques . While the second sample was better in drying speed indicator, but not better in plasticity than sample three.

The burning process is also the same, when the author tries to use the oxidation burning technique the results obtained are smooth, the glaze melts evenly. And it was beyond expectations when I found glaze that was fired by reduction, which resulted in cracks. This became an experiment where, by using the same glaze but using a different firing technique, the results obtained were also different.

Colony , which is the title of this work, is an affirmation that this work was created and displayed in groups as a manifestation of the life of radiolarians, which also form clusters. This work uses glaze with pop colors to give breath or life to radiolaria to show that it is alive, exists, and has benefits for life. This work is the result of processing clay waste which is reused by processing it in 3 formulas. The use of each formula adapted to each technique can be treated, the diversity of the properties of each clay is as rich as radiolaria which has many species. This work is a manifestation of the author's curiosity to utilize waste clay as an alternative material in ceramics that can reduce waste in the environment by elevating waste as something that is often seen as useless into something as good as new materials. This appointment is also supported by the concept of radiolaria which is rarely known but has many functions so that these two objects are able to complement each other as something complex and support in terms of empowering the environment.

The process of shaping by making holes and adding thorns is a challenge in itself, between wanting to achieve an aesthetic shape and the reality of a clay condition that is unable to support it. This horror is not only felt by the excitement when making it, but also the care when having to move it. As a result, you often have to endure broken thorns. This difficulty causes the writer to have to think long and hard about making something exactly the same, so that what is taken in this work is only the principles of morphology.

Conclusion

Every factory has its own waste problems, and ceramics factories are no exception. Ceramic factories usually have problems with liquid or solid waste either from glaze or clay. In this creation, the author came up with an idea to reuse waste clay as an alternative material in making ceramics by taking radiolaria objects as inspiration.

Waste clay becomes factory waste that looks like garbage. This raises a critical attitude and attempts to reuse it. This use was then poured out in the form of works that took radiolaria as objects. Radiolaria, which are plankton in the ocean, live and die. Plankton that live can be of benefit to human life such as maintaining the temperature of the earth and those that are dead can be useful for measuring the age of the earth or an indicator for the presence of petroleum. The benefits that can be taken from radiolaria are so great, but many people are not familiar with radiolaria. In the creation of this work, the author also wants to convey about both in terms of discourse and practice. By borrowing radiolaria objects, the author wants to reuse waste clay that is seen as useless into something that can be reused just like radiolaria which can be useful both when they are alive or when they are dead.

This waste clay research was also carried out by means of a laboratory checking process using the ICP method to determine the levels of the heavy metal Pb (lead). The levels of heavy metals such as Pb should be examined for levels in the waste in order to find out how important and urgent the waste is to be processed immediately. Also in this study, the authors used conventional oxidation-reduction techniques applied in ceramic firing as a technique for removing heavy metal content. After being examined on a laboratory scale, the heavy metal content of Pb in clay waste was 365.10 mg/Kg which when compared to the quality standard issued by the Yogyakarta Special Region Regulation of 1 mg/L or 1000 mg/Kg, the content contained in waste clay still below the standard, which means this clay is safe for the environment.

This research is basically to make unused waste clay for reuse which will then be mixed again so that the quality is equivalent or better than the new clay. This can be an empowerment, so that unused clay is not just stored or disposed of carelessly. After that, the re-processed clay will be examined to determine its quality by looking at the color, shrinkage of the clay, and plasticity. Furthermore, the clay is made to make works with printing, Coiling, pressing, plate and rotating techniques. Burning is done twice, namely burning biscuits and burning glaze. Baking biscuits is carried out for 4 hours at 750oC and burning glaze is carried out for 7 hours at 1200oC.

After the clay is burned to 1200o C the clay is tested again on a laboratory scale using the ICP method to find out whether burning in ceramics is efficient for removing or reducing Pb levels in the clay. The result after this research was that the Pb content in the waste clay that had been burned was 2.71 mg/kg which turned out that burning was an effective way to reduce Pb levels in waste clay by 99.2%.

Tests on three samples of waste clay that have been formulated then produce artistic works with sample I clay by using clay samples II and III as clay to support artistic work. The results of burning with a reduction-oxidation-reduction system make the resulting glaze cracked but can be etched separately. Calculation of costs spent on processing this clay is around 925-1025/Kg Rupiah, which is much cheaper than the price of ready-to-use clay which reaches 7500/kg Rupiah.

Bibliography

Arboleda, Cora R. 1981. Communications Research. Manila: CFA Astuti, Ambar, (2008), Ceramic Science and Manufacturing Process Yogyakarta: Arindo Nusa Media.

Baumgartner, Peter O, et al, (2006), Radiolaria Siliceous Plankton Through Time, Birkhauser verlag, Basel : Eclogae Geologice Helvetiae Swiss Journal of Geosciences, SIII-.SIV.

Borgdorff, (1998), The Reproduction of Knowledge in Artistic Research. In Biggs, Michael and Karlsson, Henrik (Eds.). The Rouledge Companion to Research in the Arts. Rotledge: London and New York.

Guntur, (2006), Artistic Research Methods, Surakarta: ISI Press. Gupta, VK and Ali, I., (2004), Removal of Lead and Chromium from Wastewater Using Bagasse Fly Ash - a Sugar Industry Waste, J. Col. Int. Sci. 271, 321-328.

Haekel, Ernest, Ernest Haekel's Artform in Nature, Germany: Rare Book Berlin.

Ijong, Frans Grubber, (2015), Fisheries & Marine Microbiology, Jakarta: PT. Rineka Cipta.

Jain, DS, (2004), Adsorption of Zinc on Bed Sediment of River Hindon: Adsorption Models and Kinetics, Journal Hazard Mater, pp. 231-239.

Jang-Soon, K., Seong-Taek, Y., Jong-Hwa, L., SoonOh, K., and Ho-Young, J., (2010), Removal of Divalent Heavy Metals (Cd, Cu, Pb, and Zn) and Arsenic (III) from Aqueous Solutions Using Scoria : Kinetics and Equilibria of Sorption , Journal of Hazardous Materials 174, pp.307-313.

Kerlinger, Fred. 1973. Foundations of Behavioral Research (2nd Edition) Holt, Rinehart and Winston.

Mattison Steve, (1998), Ceramics Two Books in One , London: Apple Press. Moeliono, Anton M., (1998), General Indonesian Dictionary, Jakarta: Balai References.

Nontji, Anugrah, (2008), Plankton Laut , Jakarta: LIPI Press.

Priadi, Cindy Rianti, Anita, Putri Patchouli and Setyo Sarwanto Moersidik. (2014), Adsorption of Zinc and Lead Metals in Liquid Waste from the Ceramic Industry by Clay Waste , Reactor Journal, Vol. 15 No. 1, pp. 10-19.

Regional Regulation No. 7 of 2016 concerning Wastewater Quality Standards.

Pinnavia, TJ, (1983), Intercalated Clay Catalysis, Science 220, pp. 365- 371.

Sahu, MK, Mandal, S., Dash, SS, Badhai, P., and Patel, RK, (2013), Removal of Pb (II) from Aqueous Solution by Acid Activated Red Mud, Journal of Environmental Chemical Engineering 1, pp . 1315- 1324.

Smith, Hazel and Dean, Roger T, (2009), Practice-Led Research, Research-Led Practice in the Creative Arts, Edinburgh: Edinburgh University Press Ltd.

Soemantoro, M, Safrin Zuraidah, Rika Nosen, (2015), Utilization of Tile Waste as an Alternative Material for Coarse Aggregate in Concrete , Vol. 1, No. 1.

Sudarmaji, (1979), Fundamentals of Fine Art Criticism, Government of DKI Jakarta, Office of Museums and History.

Susanto, Mikke, (2011), Visual Diction , Yogyakarta: Kanisius.

Tanabe, K., (1981), Solid Acid and Base Catalysis, In: Anderson, JR, Boudart, M. (Eds). New York: Spinger.

Veli, S. and Alyuz, B., (2007), Adsorption of Copper and Zinc from Aqueous Solutions by Using Natural Clay, Journal of Hazardous Materials 149, pp. 226-233.

About The Author